- Exploring the Canvas of Creativity: A Dive into Art Groups at AmazingSkills

- The Lego Group: Building Blocks of Imagination

- The Phenomenon of "Situs Slot Gacor"

- The Importance of Truck Accident Lawyers

- The Importance of Truck Accident Lawyers

- Understanding Autism in Boys

- Baby Shower Decorations

- New Page

- Exploring the World of Disney Vacation Club (DVC) Rentals

- 카지노 커뮤니티 순위에 대한 고찰

- Wycena aut - jak ustalić wartość swojego samochodu?

- The Thrills of Pong Table Tennis

- Prečo si vybrať hranie kasínových hier v Librabet: Top 5 výhod

- The Exciting World of Judi Slot Dewa66

- The Ultimate Guide to San Diego Photo Booth Rental

- New PageAtlanta Car Accident Attorney: Your Trusted Legal Partner

- Features of Fire Insurance by bimakavach

- New PageEnhance your exhibition stand with an efficient design in the Netherlands

- King Bedsheets: A Review by Granjoy

- The Beauty of Beige Bed Sheets: A Review of Granjoy

- TEXAS88: Platform Demo Slot Pragmatic Play yang Berkualitas

- TEXAS88: Solusi Terbaik untuk Kebutuhan Anda

- Texas88

- CGL Insurance: Protecting Your Business

- The Essential Pool Equipment Every Pool Owner Needs

- TEXAS88: Alles wat je moet weten over Utahfishinginfo

- TEXAS88: Een Nieuwe Ster aan de Horizon van Veganistisch Voeding

- Bronchosedal Codeïne Kopen Nederland

- Codeine Kopen Kruidvat: Een Overzicht van Medicatieonline

- Codeïne Kopen in Spanje

- Ritalin Kopen Telegram: Een Verkenning van Digitale Apotheek

- Oxazepam Teva 10 MG Kopen bij MedicatieOnline

- Oxazepam Kopen in Spanje

- Temazepam of Oxazepam Kopen bij Bestellenmedicijnen

- vc

- Verschil Zolpidem en Zopiclon

- Zolpidem Kopen Kruidvat: Een Veilige Optie voor Slaapstoornissen

- Zopiclon Autorijden: Wat U Moet Weten

- Slaapmiddel Zopiclon: Een effectieve oplossing voor slapeloosheid

- Hoe Lang Duren Ontwenningsverschijnselen Lorazepam

- Lorazepam Apotex niet leverbaar: Een kijkje bij Medicatieonline

- Zopiclon Verslavend

- Diazepam Bestellen: Veilig en Betrouwbaar bij Deapothekeronline

- Book Covers for Sale: Enhancing Your Reading Experience with Creativeparamita

- Interview Preparation in the AI Era: Status and Implications

- Chicago Wedding DJ: Elevated Event Design

- The Writing Generator: Revolutionizing Content Creation

- Exploring the World of 2up Sports: A New Era of Sports Social Entertainment

- St. Joseph Car Accident Attorney: Your Trusted Ally in Pursuit of Justice

- Life Insurance Denial: When to Seek Legal Assistance

- The Impact of ChatGPT on the Future of Writing

- The Importance of Hiring an Oakland Disability Lawyer

- Health & Beauty: The Key to a Happy and Confident Life

- The Power of Magic Mushroom Chocolate: A Journey into Mind and Spirit

- 토토 추천에 대한 블로그 포스트

- The Future of Education: Unlocking the Potential of Every Student

- Τα καλύτερα καζίνο με μπόνους χωρίς κατάθεση στην Ελλάδα

- เว็บพนันบอล: ช่องทางสำหรับคนรักฟุตบอล

- San Diego Molestation Attorney: Seeking Justice for Survivors

- Hemet Car Accident Lawyer: Your Guide to Legal Support

- 먹튀없는 토토사이트에 대한 이해

- Building Contractors in Essex: Your Solution for Construction Projects

- Am I Nonbinary Quiz: A Self-Reflection Journey

- Best All-Season Tires: A Comprehensive Review

- Boosting Instagram Engagement: Tips from Coach Digital Marketing

- Navigating the World of Car Insurance with JustCarInsuranceQuote

- Explore effortless efficiency with OpenAI-powered web databases

- Enhance Your Digital Security with PasswordManager.plus

- What is a Google XML Sitemap?

- The Marvel of Automatic Ethanol Fireplaces

- Exploring Janitor AI Free: A Revolution in Automation

- Embracing the Future: Growing Your YouTube Channel with Bitcoin

- A Comprehensive Guide to Check Printing Software

- Discover the Magic of Premade Book Covers with Creative Paramita

- The Ultimate Guide to Buying Anime Keychains

- Let Your Inner Pooh Bear Shine: Take The Winnie The Pooh Test Today!

- Altcoin News with BitCrypto Gazette

- The Importance of Local Moving Quotes in Framingham

- Car Grooming vs Car Detailing: Which One is Right for Your Vehicle?

- The Ultimate Moving Solution: Man with a Van Bedford

- Enhance Your Digital Security with PasswordManager.plus

- Unleashing the Ultimate Bachelor Party: A Comprehensive Guide

- Steroids in Thailand: A Closer Look

- Steroids in Thailand: An In-Depth Look into SARMs Square

- The Power of Resizing: Transforming Your Images with Resize

- The Beauty of Two Stone Engagement Rings: A Symbol of Love and Style

- Master Your Interview: 5 Tips for Success

- Quillbot Review 2024: Revolutionize Your Writing with AI

- The Magic of Bali Massage: A Deep Dive into Indonesia's Holistic Treasure

- The Charm of Baby Boy Grandma Onesies

- Buy YouTube Monetization Package: A Game-Changer for Content Creators

- Unwrapping the World of Wireless Mouse Suppliers

- A Deep Dive into a Tofu Cat Litter Factory

- Best Dog Boarding in Mount Prospect, Illinois: A Comprehensive Review by Pet Care Check

- Finding the Perfect Pet Care in Mount Prospect, IL

- Exploring the World of Slot Depo25k

- Exploring Viral99: A Digital Phenomenon

- Descobrindo a Casa de Massagem Santo André

- Exploring the Modern Vape Shop

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Water Dispenser for Office Singapore: An Essential Guide

- Laweta - Twój najlepszy wybór w sytuacjach awaryjnych

- Elite Society London: A Premier Destination for High-Class Escorts in London

- Embark on a Journey Through the Vast World of Classifieds with Escrow Ads

- Economistas y Juristas: Pilares de la Sociedad

- sdjc as

- sdjc as

- sdjc as

- sdjc as

- The Power of Sound: Elevate Your Experience with Zerest Audio's Sports Earphones

- sdjc as

- Discover the Power of Sound: Unleashing the Magic of Sports Earphones with Zerest Audio

- Affordable Earbuds With Good Bass: Unleashing Superior Sound With Zerest Audio

- Score Big With Cheap Soccer Jerseys From Mailloten

- Slot Online di JosephCornellBox: Pengalaman Bermain yang Fenomenal

- Understanding Standard Window Sizes: A Guide to Common Window Sizes

- Standard Window Sizes: A Comprehensive Guide

- Understanding Standard Window Sizes

- Guard Alaska Bear Spray: Your Ultimate Defense Against Bear Encounters

- The Power of Tactical Pens: More Than Just Writing Tools

- Aztec Bonanza - A Deep Dive into the Enthralling World of Online Slots

- Unleashing the Power of Pragmatic Play: An In-Depth Look at Slot Gacor Gampang Maxwin

- The Rise of Wealth in Africa and the Importance of Protecting Your Fortune

- Belize Real Estate Search: Your Guide to Finding Your Dream Property

- Residential Movers Boston: A Comprehensive Guide

- Understanding Google Maps Timeline: A Comprehensive Guide

- The Ultimate Guide to Mileage Tracker Apps: Mileagewise and Beyond

- An In-depth Look into Nicopods: The Future of Tobacco-Free Nicotine

- Nicopods: The Tobacco-Free Future of Nicotine Products

- sdvjk sd

- The Art of Book Cover Designing: A Deep Dive into CreativeParamita

- sdvjk sd

- sdvjk sd

- The Game Changer in Peptide Preparation: PrimePeptides' Peptide Calculator

- HDISBJD\

- Pattern Making in Clothing: Simplifying Your Fashion Vision with Joiluv

- The Exciting World of Eurojackpot Lottery

- The Exciting World of Eurojackpot Lottery

- skmcjsc

- skmcjsc

- Decked Out Builders: The Ultimate Deck Installer

- skmcjsc

- Decked Out Builders: Crafting Unforgettable Outdoor Spaces

- Лотерея EuroMillions: Як виграти великий

- emahami Cara Login di Judi89

- k wnjc

- Mengenal Agen Slot Pragmatic

- Mengenal Lebih Dekat Link Ratu89

- Menjelajahi Slot Online Terpercaya

- The Power of OEM Watch: A Closer Look at Romlicen

- Unveiling the Fascinating World of Art Collection at CharlesSMoore

- The Art Curator's Role at Charlessmoore

- Pin Up Казино

- skdksd sk sk

- The Essential Guide to Windows and Doors

- Windows and Doors: Key Elements of Your Home

- Discover the Ancient Art of Yoga in Rishikesh with MagicMomentPhotoBooth

- The Journey of Yoga: Experience Teacher Training in Rishikesh at Rishikul Yogshala

- Why You Need a Personal Injury Lawyer in Katy

- The Power of Email: The Key to Success in EncryptedSpaces

- Experience the Magic of Cinderella Cleaning

- Mengenal Lebih Dekat API77 dari treeremovaledmonton

- Mengenal Lebih Dekat API77 dari treeremovaledmonton

- Real Estate Belize: A Hidden Gem in the Caribbean

- Understanding Vape Pods: A Comprehensive Guide

- The Latest Scoop on Gambling News

- Top-7 Libreng No-Deposit Casino Bonuses na Magagamit sa Pilipinas

- Discover the Art of Yoga: Enroll in a 200-Hour Yoga Teacher Training in Rishikesh

- Batman Merchandise - A Symbol of Vigilantism and Justice

- Bernedoodle Puppies For Sale: Find Your Perfect Companion at Prairie Hill Puppies

- Unearthing the Magic of Bernedoodles: Meet Prairie Hill Puppies

- Slot Thailand HOME4D: Permainan Hiburan Berkualitas Tinggi

- shbhcbsk

- shbhcbsk

- shbhcbsk

- A Comprehensive Guide to Santa Rosa Criminal Defense Attorney Services

- shbhcbsk

- Master the Art of Ecstatic Dance DJing with Online Training

- The Go-To Long Island Personal Injury Lawyer: Palermo Law

- Navigating the Turbulent Waters of Divorce with a Suffolk County Divorce Lawyer

- Choosing the Best T-Shirt Print Machine for Your Home Business: A Guide

- The Ultimate Guide on How to Make DTF Transfers: Elevate Your Textile Printing with Galaxy Press

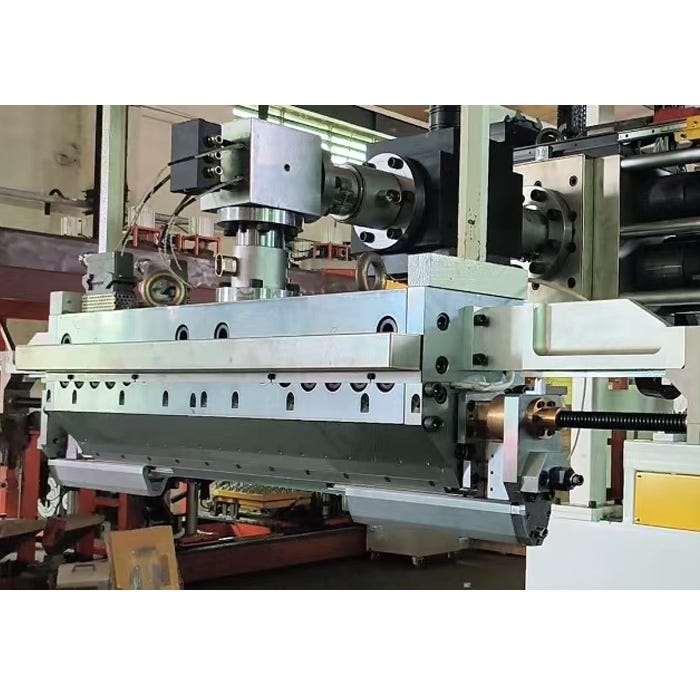

- Spotlight on Salem Design and Manufacturing

- j k

- Discover the Best Invisalign Deals at CareDentalTysons

- Dr. Rahat Aziz: Revitalizing Dentistry at Care Dental Tysons

- Generating YouTube Tags with Famoid: A Comprehensive Guide

- Unleash the Power of Famoid's YouTube Tag Generator Tool

- hn cjj\

- hn cjj\

- Understanding Blow Molding Machines: The Tech-Long Revolution

- A Revolution in Beverage Industry: The Aseptic Filling Line from Tech-long

- Psicóloga en Barcelona: Más Que Una Profesión, Una Vocación

- The Essential Role of a San Jose Divorce Lawyer

- Consulta de Veículo no CNPJ: A Importância da Análise de Dados

- The Power of a Ready Ecommerce Website: A Look at Cartcreators

- Best Sites to Buy Twitch Followers: A Comprehensive Guide

- Consulta de Veículo no CNPJ: Uma análise aprofundada

- Menang Besar dengan Slot Gacor di WinSlot

- V9BET: Nhà Cái Trực Tuyến Hàng Đầu Việt Nam

- FDGF

- Understanding Medical Malpractice: Insights from The Moses Firm

- Mugs for Men: A Perfect Blend of Function and Style

- Understanding Medical Malpractice: A Guide to Getting Legal Help in Marietta with The Moses Firm

- The Unseen Power of Temp Mail: A Comprehensive Guide

- The Best Custodian for Your Gold IRA: A Deep Dive

- Eletroestimulação: A evolução da fisioterapia na Clinimeso

- Unraveling the Power of RFID Labels

- Akcyza za samochód z USA - wszystko, co musisz wiedzieć

- Jak zapłacić akcyzę za samochód z USA

- Slot Gacor Hari Ini: Panduan Untuk Pemain Slot Online

- Slot Gacor Hari Ini: Sebuah Panduan untuk Pemain Slot Online

- Navigating Your Divorce with an Atlanta Divorce Attorney

- Kushibada: Uniquely Crafted Luxury with a Touch of Valor

- Understanding the Role of a Lawrenceville Medical Malpractice Lawyer

- The Moses Firm: Advocacy and Justice for Marietta Medical Malpractice Victims

- The Unparalleled Benefits of Belleza's Home Services: A Comprehensive Look at Our Maid Cleaning Service

- Belleza’s Home Services: The Role of a Housekeeper

- Alanya Travel Guide: A Jewel on Turkey's Southern Coast

- j vj

- Expanding Your Understanding of RFID Tracking Labels

- Revolutionizing Asset Tracking with RFID Labels

- Elevating Your Business with Hotel SEO: A Comprehensive Guide

- Discover the Comfort of Queen Size Royal Blue Bed Sheets by CGK Unlimited

- Cancelación de Deudas en Barcelona: Un Segundo Comienzo

- The Secret to Muscular Growth: Damiana Leaf

- Keajaiban Eletroestimulação: Transformasi Kesehatan dan Kecantikan di Clinimeso

- Affordable Airpod Alternatives: Experience Unparalleled Sound Quality With Zerest Audio

- Affordable Earbuds with Good Bass: A Review of Zerest Audio

- React JS Development Services by FuturByte

- Why You Should Consider Hiring a Private Investigator from Phenix Investigations

- nn nbn nn n

- AliExpress Promo Code: A Key to Incredible Savings

- DGMarks: Uma Agência de Marketing Digital Inovadora

- A Comprehensive Guide to Dumpster Rental in Detroit

- Gacor123: Platform Game Online Terpercaya di Indonesia

- Pengenalan ke Gacor123: Pilihan Terbaik Anda untuk Game Slot Online

- The Best Home Renovation Services For Transforming Your Home

- Bathroom Renovation in Toronto: Reimagining Your Most Intimate Space

- The Right Choice for Your Basement Renovation: The Right Guys

- Transform Your Home with Home Extensions

- Custom Kitchen Cabinets Toronto: Enhance Your Home with The Right Guys

- Exploring the Benefits of Laneway Homes in Toronto

- Gacor123: Platform Game Online Terbaik Menyediakan Permainan Judi Slot Paling Gacor

- The World of DJ TOGEL: Master of Beats

- Gacor123: Platform Game Online Terbaik dan Terlengkap

- افضل عسل في السعودية: الريف النجدي

- Link Gacor123: Tempat Bermain Game Judi Online Terpercaya

- The Power of Custom Gift Boxes: Elevate Your Brand with Confete Party Box

- Elevate Your Brand with ConfetePartyBox: The Power of Client Gifts

- Exploring the Benefits of HOA Billing Software

- Exploring the World of Candid Leggings

- Link Alternatif Koitoto: Pilihan Cerdas Untuk Penggemar Judi Online

- Lost Mary: Embracing Innovation with the Prefilled Pod Kit

- The Rise of the 36-Inch TV: A Comprehensive Guide

- Large HD Tube: A Revolutionary Product

- The Ultimate Guide to Trex Decking End Caps

- Discover the Magic of Faux Brick Wall Panels 4x8 from GlobalSources

- Discovering the World of 28 Inch Smart TVs

- Finding the Perfect Aux Cord Extension: A Comprehensive Guide

- TGM Air Conditioners: A Comprehensive Review

- The Ultimate Guide to 20 Inch Smart TVs

- Discovering the Best Replica Websites: A Comprehensive Guide

- The Renaissance of White Slouch Socks: A Comprehensive 2024 Guide

- How Long Does Shein Take to Deliver? A Comprehensive Guide

- AliExpress vs Temu: The Battle of Online Marketplaces

- Men's Eyeglasses Fashion Trends: A Look into 2024

- บุหรี่นอก: ความคิดเห็นและจริงอยู่ที่ไหน?

- Slot Gacor: Fenomena Baru dalam Dunia Permainan Online

- Slot Gacor Gampang Menang: Rahasia Dibalik Popularitasnya

- The Ultimate Guide to Mastering the Art of CNC Drilling Machine

- The Future of Vaping: Exploring the Prefilled Pod Kit by Lost Mary

- Elevate Your Home Interior with a 70 Inch Table Top Mirror

- virtual dissection table manufacturer: Consistency in B2B Quality

- Revolutionizing Community Management with ADDA's HOA Billing Software

- 6mm Motor: Unlocking the Power of Adjustability

- Santa Rosa CA Home Sales: Navigating the Market with Diamond Group Estates

- Discover the Best Deals at Miami Furniture Store: Miami Furniture Outlet

- Revolutionizing Urban Lighting: The Power of the QULON C2 Street Light Controller

- Discover the Best Furniture Miami Has to Offer

- Best Data Deals: Finding the Perfect Plan in North Carolina

- Order Now and Pay Later: Transform Your Space with Miami Furniture Outlet

- Exploring the Benefits of Reciprocating Endo Motor: A Joyful Journey

- Compressor Dryer: An Essential Component for Efficient Air Compression

- OEM Hyaluronic Acid Dermal Filler: A Comprehensive Guide

- Exploring the Potential of a 1000 kWh Battery Bank

- The Rise of Lithium Battery Factory: Revolutionizing the Energy Storage Industry

- Carbon Filter Cartridge Making Machine: Revolutionizing the World of Filtration

- Unleashing Innovation: The Future of Electronic Projects

- The Bright Future of Manufacturing: Embracing Smart Technology

- The Amazing Rise of LED Studio Screen: Lighting Up the Entertainment Industry

- Stretch Spandex Fabric: The Trendy and Flexible Choice

- The Power of Fast Gas: Revolutionizing the Culinary Scene

- Discover the Best One-to-One Quran Teacher for Personalized Online Learning

- The Revolution of Sound Monitoring: Navigating the Future of Acoustic Awareness

- Discover the Versatility and Charm of Custom Tote Bags

- UFABET เว็บหลัก: การปฏิวัติโลกของบล็อกเชนด้วย BSC NEWS

- Unlocking Convenience: Car Unlock Service in Sherwood Park

- เว็บตรงคาสิโน: การเปลี่ยนแปลงของอุตสาหกรรมบล็อกเชน

- 먹튀검증사이트: 안전한 베팅의 필수 조건

- WarrenGroup: Pioneering Quality and Innovation in Home Solutions

- Revolutionizing Home Design: Discover the Excellence of Derchi Windows and Doors by Warren Window

- The Power of Effective Website Design: How Aurora Web Design Pros Can Transform Your Online Presence

- 완벽한 가슴라인을 위한 가슴수술: 마인성형외과의 특별한 접근법

- 韓国 整形: 美の新たな基準

- リジュラン: 美容医学の新たな地平を切り開く

- The Hidden Dangers of Secondhand Vape: What You Need to Know

- The Ultimate Guide to Male Fertility Supplements: Enhancing Your Journey to Fatherhood

- Discover the Pokémon Ecchi Version: A Unique Gaming Experience

- 가슴수술: 하루 만에 가능한 변화

- The Sparkle Revolution: Unveiling the Iced-Out Watch

- 카지노 사이트: 신뢰성과 안전성을 갖춘 카지노 랜드

- 한국에서 합법적인 온라인 카지노 사이트를 찾는 방법

- Revitalize Your Space with Kitchen Respray Manchester

- Homestay Melaka dengan Kolam Renang Peribadi: Pengalaman Unik dan Mewah

- Abogado Contencioso Administrativo Sabadell: Su Guía Completa para la Resolución de Conflictos Legales

- The Art and Science of Book Cover Design: Elevate Your Story with Creative Paramita

- Unlocking the Secrets of Korean Skincare: Why It's Taking the World by Storm

- The Essential Guide to Jewelry Tools: Elevating Your Craft with SEP Tools

- Illuminating the Future: The Power of Architectural Outdoor Lighting

- Siivouspalvelut: Miksi Ammattilaisten Valinta Tekee Eroa

- Revolutionizing the Industry with Iny Tech's Configurable Transmission System

- Navigating the Legal Maze: The Essential Role of a Personal Injury Lawyer in Las Vegas

- 온라인 슬롯: 신뢰할 수 있는 카지노 슬롯 사이트의 선택과 게임 가이드

- Understanding Mental Health: A Journey to Better Well-Being

- Understanding Diamond Watch Cost: A Comprehensive Guide

- 먹튀검증: 안전한 토토 사이트 이용을 위한 필수 가이드

- The Ultimate Guide to Online Gambling: Finding Your Perfect Platform with Gamblerstime

- kkamkThe Heart of Smart Street Lighting Control: Street Light Controller QULON C

- Windows 10: Das Betriebssystem der Wahl für moderne Geräte

- The Revolutionary BLDC Technology: Shaping the Future of Industries

- Anatomical Models Suppliers: Revolutionizing the Field of Medical Education

- Exploring the World of PM Components

- The Advancements of Field Programmable Gate Array Technology

- Medical Device Component Manufacturers: The Backbone of Healthcare Innovation

- Revolutionizing the Future: Curved Lipo Battery

- The Best Hybrid Inverter: Revolutionizing Energy Efficiency

- Solenoid Valve Terminal: Enhancing Efficiency and Control

- Engineering Silicon Nitride Ceramics: Revolutionizing Problem-Solving in the Tech Industry

- Genshin Impact Top Up Website: The Ultimate Guide to Enhancing Your Gaming Experience

- Sleeveless Maxi Dress Casual: A Guide to Quality Assurance

- 온라인 슬롯: 다양한 게임과 신뢰할 수 있는 사이트 추천

- 가슴 지방이식: 자연스럽고 볼륨감 있는 가슴을 위한 선택

- Почему стиральная машина остановилась с водой? Как решить проблему

- The Modern Cookbook: Revolutionizing How We Cook

- Mastering Appliance Repair: Ensuring Seamless Functionality with Mission Viejo Appliance Masters

- The Art and Science of Scar Camouflage: Transforming Imperfections into Confidence

- Discover Luxury Living in Conyers, GA: Emblem Conyers

- Mengungkap Rahasia Cheat Slot: Cara Baru Bermain Slot Online dengan Mudah

- Understanding Gout Symptoms: A Comprehensive Guide

- Discovering Senior Home Care in San Francisco: A Gateway to Independent Aging

- dskdskdskd

- The Art and Impact of Book Cover Design: A Guide to Creative Success

- Pentingnya Vitamin C: Manfaat, Dosis Harian, dan Cara Mendapatkannya

- Discover the Future of Urban Living with KüL Condos

- Discover the Allure of Iris Estates: A Modern Retreat in King City

- Menjelajahi Dunia Toto Slot: Panduan Lengkap untuk Pemain

- IPTV Pro : La Révolution de la Télévision à la Demande

- Menyelami Dunia Judi Tangkasnet: Panduan Lengkap untuk Pemain Pemula dan Berpengalaman

- IPTV Premium : Révolutionner Votre Expérience de Télévision

- 물론입니다! 다음은 한국의 온라인 슬롯 사이트 순위와 슬롯 머신 게임 정보를 포함한 1000단어 분량의 한국어 기사입니다.

- Indravil Apotheke: Entdecken Sie die Vorteile der Indravil Kapseln

- Unlocking the Mysteries of the Tarot Horoscope: A Journey Through the 12 Houses

- Abogado Familia Sabadell: Navegando por el Derecho Familiar con Corominas Fernández Abogados

- Cómo Elegir el Mejor Abogado de Divorcio en Sabadell: Guía Completa para Manejar tu Separación Familiar

- Embracing Happy Aging: The Best Senior Care Services in Phoenix with Careyaya

- The Crucial Role of an Electronic Components Distributor: Why Origin Data is Your Best Choice

- The Royal Treatment: Why Knights of Cleaning Reigns Supreme in Area Rug Cleaning

- Processing Aluminum Nitride Ceramics Manufacture, Please

- Is it Worth Buying Gems in Brawl Stars?

- 안전한 온라인 베팅을 위한 먹튀검증의 중요성: mthold의 안전한 놀이 공간

- The Timeless Beauty of Mandala Wood Carving: Bringing Peace and Art into Your Home

- The Ultimate Guide to Malaysia Online Slot Games: Discovering the Best at Jadiking

- Your Essential Guide to Finding the Best Locksmith in Edmonton

- ìm Hiểu Về V9bet và Quaysogame: Lĩnh Vực Giải Trí Online Đang Được Nâng Cao

- Finding the Right Private Duty Caregivers in Boston: A Step-by-Step Guide for Peace of Mind

- Memilih Sunscreen yang Tepat: Mengatasi Jerawat dan Melindungi Kulit Anda

- The Future of Business Communication: Finding the Right Phone Service Providers in Your Area

- DesignByWarren: Revolutionizing Windows and Doors with Precision and Innovation

- Pentingnya Vitamin C untuk Kesehatan Kulit: Panduan Lengkap untuk Menjaga Kesehatan dan Kecantikan Anda

- The Best Bonuses for Cricket Lovers: How to Maximize Your Sports Experience

- The Top 5 Fantasy Betting Apps to Transform Your Wagering Experience

- Elevate Your Gifting Game with Gift Boxes in Bellevue, Washington: Spotlight on Confete Party Box

- Elevate Your Corporate Gifting Strategy in Mercer Island and Bainbridge Island, Washington with Confete Party Box

- Discovering the Best Catering Services in Kuala Lumpur: A Culinary Journey

- Car Cleaning Geelong: The Ultimate Guide to Keeping Your Vehicle in Top Shape

- The Ultimate Payment Gateway for International Payments in India: Payomatix

- Importanța Recenziilor Google în Creșterea Afacerii Tale

- The Ultimate Guide to Finding Quality Car Parts: Your Go-To Auto Store

- Your Guide to a Hassle-Free Move with Pack Dat & Geaux Movers in Slidell

- Dlaczego Strony WWW Są Kluczowe dla Rozwoju Twojej Firmy?

- Revolutionizing Forex Brokerage: The Essential Role of a Modern CRM Provider

- Zdrowie: Kluczowe Aspekty, Które Wpływają na Nasze Życie

- Optymalizuj Zarządzanie Rezerwacjami Dzięki Darmowemu Systemowi Rezerwacji

- Thruster Finance: Revolutionizing DeFi with User-Friendly Innovation

- The Rise of Free Cam to Cams: A New Era of Online Interaction

- Unraveling the Mystery of Deadlock Cheats: A Deep Dive into Gaming Exploits

- The Essential Guide to HVAC Maintenance: Keeping Your System in Top Shape with Hot Cold Air

- 888Starz: Ваш Надежный Партнер в Мире Спортивных Ставок и Казино в Узбекистане

- Prestige Raintree Park: Redefining Luxury Living in Whitefield, Bangalore

- DesignByWarren: Revolutionizing Windows and Doors with Precision and Innovation

- Exploring the Excellence of Derchi Windows and Doors: A New Standard in Home Improvement

- The Bioprocessing Summit: Where Innovation Meets Industry

- The Ultimate Guide to Best SEO Web Hosting: Boosting Your Online Presence

- The Rise of Soccer Full Match Streaming: A Game-Changer for Fans Worldwide

- The Power of Graphic Design in the Digital Age

- The Ultimate Guide to Windows Cleaning: Transform Your Home with Sparkling Clear Views

- Mengungkap Rahasia Slot Gacor: Panduan Menang Besar di RRQ88

- Navigating Opportunities: The Journey from Berlin to NIE Barcelona

- Sound Wave Art: A Unique and Personal Gift

- The Power of a Financial Dashboard: Revolutionize Your Portfolio Management

- Menjelajahi Dunia Rolet Online: Sensasi dan Strategi dalam Permainan Kasino Daring

- Winning Plus: Menyelami Dunia Kasino Terbaik di Filipina

- Navigating the Green Pathway Environmental Impact Assessments in Project Planning

- ¿Por Qué Es Crucial Contratar a un Abogado Penal en Barcelona?

- Understanding Payout Disbursal: Transforming Payments with Payomatix

- Unlocking the Thrill of Sports Betting with JITABET: Your Ultimate Guide to Winning Big

- Slot Gacor: Memahami Fenomena Populer di Dunia Perjudian Online

- Menjadi Juara di Dunia Slot Online: Mengapa VIP77 adalah Pilihan Terbaik Anda

- The Ultimate Gaming Experience with Khela88: Your Gateway to Winning Big

- Exploring the Exciting World of the N8Casino App: Your Ultimate Guide to Winning Big

- Exploring Raja Baji: The Ultimate Destination for Online Gambling Enthusiasts

- The Rise of Rechargeable Disposable Vapes: A Game-Changer in the Vaping Industry

- Discover the Thrill: Why Baji Live Betting is Your Ultimate Online Baji Site

- Exploring the Thrills and Opportunities of Betting with JITAWIN

- The Ultimate Guide to Six6 Bet: Revolutionizing Gambling in Bangladesh

- Betwinner Télécharger : Profitez de Paris Sportifs à Portée de Main

- Off-Stamp Flavors: Breaking the Mold in the World of Taste

- Unlocking the Power of Book Cover Design: Crafting Covers That Captivate and Sell

- 온라인 슬롯: 최고의 슬롯 게임을 찾아서 – Sanatos Slot의 가이드

- Cheap Cigarettes: A Look at Affordability and Smoking Habits

- Mengungkap Hubungan Antara Jerawat dan Makanan: Fakta atau Mitos?

- Understanding the Role of a DPM Doctor: Insights from Dr. Alex Yanovskiy

- Heets Cigarettes: A Modern Alternative to Traditional Smoking

- Discover the Best Digital Printing Services in Los Angeles: Elevate Your Brand with LA Print Center

- Discover the World of IQOS HEETS: A New Era in Tobacco Enjoyment

- Clinica Stomatologică: Inovație și Excelență în Îngrijirea Zâmbetului

- JUUL Kits: The Perfect Vaping Companion for Every Lifestyle

- Memperbaiki Elastisitas Kulit dengan Rejuran: Solusi Kecantikan dari Klinik Bedah Plastik MINE

- Understanding Your Rights After a Portland Truck Accident: Insights from a Local Lawyer

- The Ultimate Guide to JUUL Pots: Everything You Need to Know

- Mengapa Memilih jawatogel: Solusi Terpercaya untuk Keluaran Togel Terlengkap

- The Vital Role of a Houston DWI Lawyer: Defending Your Rights and Freedom

- A Comprehensive Car Seat Review: The Top Choices for Safety and Convenience

- How to Clean Your Dishwasher with Baking Soda and Vinegar: A Step-by-Step Guide

- The Power of an Authentic Tibetan Bracelet: Unlocking Harmony and Balance in Your Life

- The Best Weight Training Shoes for Women: Elevate Your Performance with CASTIRON LIFT

- Mengapa Memilih Net88 untuk Taruhan Bola? Menyediakan Pengalaman Bermain yang Tak Terlupakan

- Destinazioni di Surrogacy in Europa: Il Tuo Percorso verso la Maternità con il Prof. Feskov

- Revolutionizing Content Creation with AI Video Generators: The Power of CopyCopter

- Effortless Moving with Man and Van Northampton: Your Guide to Stress-Free Relocations

- Unlocking TikTok Success: The Power of Buying Views for Your Posts

- Transform Your Space: A Comprehensive Guide to Bergen County Home Additions

- Transforming Spaces with the 8 ft Window: The Pinnacle of Modern Design

- Elevate Your Space with an 8 ft Patio Glass Door: The Warren Windows Approach

- The Benefits of a 16 x 12 ft Insulated Garage Door: A Comprehensive Guide

- The Best Place to Buy LoL Smurf Accounts: Why Kaynshop Stands Out

- Packman Disposable: The Rising Star of the Vaping World

- 피망머니상: 피망 포커 머니/포커 칩 가격 및 거래 방법 가이드 (2024년 9월)

- Discovering the Best Massage Chair: Your Guide to Unparalleled Relaxation

- KI-gestützter Vertrieb: Die Zukunft des Verkaufs mit cegtec

- Discover the Best in Online Gambling: Why OCS8 is the Trusted Online Casino in Malaysia

- Menangkan Jackpot Besar dengan Slot Gacor di KELAS99

- The Ultimate Guide to Ceramic Coating in Geelong: Why AZ Car Detailing is Your Top Choice

- The Role of a Colorado Criminal Defense Attorney: Defending Your Rights in Castle Rock

- Boost Your Social Media Presence with InstaBoost: The Ultimate Guide to Digital Success

- The Power of Social Media Promotion: Strategies for Success with InstaBoost

- Menyambut Era Baru Permainan Online: Menyelami Dunia KDG789

- Transforming HR with Workant: The Power of HR Software for Modern Businesses

- Unlocking Excellence in Commercial Cleaning: Why ISS Cleaning Leads Perth

- Why White Tent Rentals are Essential for Your Outdoor Event

- The Allure and Functionality of 6 Ft Wide Big Windows: A Deep Dive into Modern Design

- The Ultimate Guide to 14 ft Wide Insulated Garage Doors: Enhancing Efficiency and Style

- Boosting Your TikTok Strategy: Why You Should Buy Custom TikTok Comments

- AGV Supplier: The Future of Automated Solutions

- Endo Rotary Files: Revolutionizing Dental Endodontics

- The Rising Popularity of Filipino Maids: Why They’re in High Demand and How to Choose the Right One

- Understanding Sleep Apnoea: Symptoms, Causes, and Solutions

- Unlocking Success: The Role of PSLE Tuition in Shaping Academic Futures

- A Comprehensive Guide to Tooth Implants: Choosing the Right Clinic in Abu Dhabi

- Exploring the World of AMR Automation in Kansas

- Discover the Excitement of Slot Gaming with GoJackPot

- The Enduring Appeal of Marlboro Red Cigarettes: A Classic Choice for Smokers

- The Future of Online Gaming: Why Iwin is the Game-Changer You’ve Been Waiting For

- The Comprehensive Guide to 10 ft Insulated Garage Doors

- The Advantages of 6 x 4 ft Windows: A Comprehensive Guide

- Garage Door Repair Hamilton: Your Guide to Expert Solutions

- Cincinnati Domain Hosting: Unlocking Your Digital Potential

- The Rise of PIFF CARTS: Revolutionizing the Vaping Experience

- How to Write a CV for the Creative Industry

- Unlocking the Mysteries of LSD: Euphoria Chems' Premier Offerings in the UK

- The Ultimate Guide to Man and Van Services in Kettering: Your Trusted Moving Partner

- hbaa

- Understanding USB Camera Modules: A Comprehensive Guide

- The Best eBikes for Adults: A Comprehensive Ride Review

- The Ultimate Guide to Kitchen Remodeling in Wellington: Transform Your Space with renovisionkb

- The Power of a Digital Marketing Agency: Unlocking Business Potential in the Digital Age

- Zenir | Maternity Scrub Top: Where Comfort Meets Sustainability

- 해외배팅사이트: 안전하고 효율적인 선택, 벳8코르

- Abogado Penalista: Tu Aliado en Momentos Difíciles

- The Thrilling World of Drone and Remote-Control Car Racing

- LSR Engineering Consultancy Services: Enhancing Understanding and Innovation

- Great Curved LED Screen Panel: The Future of Display Technology

- Best Fabric for Leggings

- Exploring the World of Touch Screen Vending Machines

- Adapting Features to Customer Needs: The Versatile 1.14 Inch TFT Module

- Meeting the Needs and Expectations: USB Rechargeable Battery

- Advantages of Programmable Logic Controllers (PLC)

- Realize How Manufacturing Curtains Can Enhance Your Business

- Exploring Why Motion Control Technologies Aren't Just Add-Ons?

- What Are the Key Benefits of Battery Backup Power Supply for Home?

- Are Electric Boom Lifts the Future of Aerial Work Platforms?

- Empowering the Next Generation of Girls: How Girls For A Change is Shaping the Future

- The Thriving Landscape of Online Casino Malaysia: A Comprehensive Guide

- Discovering the Best Online Casino Malaysia: A Comprehensive Guide

- The Beauty and Functionality of 20 Gallon Decorative Pots

- Wireless Dog Fence and Collar: A Comprehensive Guide to Keeping Your Pet Safe

- The Ultimate Guide to Wireless Dog Fences for Small Dogs: A Smart Choice for Pet Owners

- The Art of Book Cover Design: Crafting First Impressions that Sell

- Windows 11 Kaufen: Ihr Leitfaden für das Beste aus Ihrem Betriebssystem

- Diamond Face Shape Hairstyles for Men: A Comprehensive Guide

- Discovering Florists in Shrewsbury: Where Elegance Meets Nature

- Mengatasi Dagu Ganda: Solusi Modern dari Klinik Bedah Plastik MINE

- Warren Windows and Doors: Elevating Home Aesthetics and Security

- Exploring the Future of Windows and Doors: Why China WDMA Stands Out

- Memahami Perbaikan Garis Rahang: Solusi untuk Jawline yang Kendur

- Unpacking the Buzz: Why Backpack Boyz Carts Are Taking Over the Vape Scene

- Discovering the Excellence of Backpack Boyz Disposable Vapes

- Furnace Replacement: Why and When to Consider Upgrading Your Heating System

- Understanding Your Rights: The Role of a Bus Accident Lawyer

- The Best Retinol Body Lotion: A Game-Changer for Your Skin Health

- Beyond the Nonsense … There Is a Path: A Journey of Self-Discovery Through Writing

- Transforming Spaces with WarrenWindow: The Future of Windows and Doors

- WDMA: Revolutionizing Windows and Doors for a Sustainable Future

- Things to Do in Springfield, MO: Your Ultimate Guide to Adventure

- HIPAA Compliant Email: Safeguarding Healthcare Communication in the Digital Age

- Embrace Freedom: The Rise of Disposable Vape Pens

- The Rise of Disposable Pod Systems: A New Era in Vaping

- The Ultimate Guide to Movers and Packers in Dubai: Making Your Move Hassle-Free

- Unlocking the Power of Online Employee Recognition: Transforming Engagement with HiFives

- Finding the Right No-Fault Physical Therapist Near Bushwick: A Guide

- The Ultimate Guide to Bob Wigs: Transform Your Look with WIGSXHAIR

- The Future of Real Estate Development: Building Wealth and Sustainability with Balfour Hamilton

- The Allure of Kool Menthol: A Refreshing Choice for Tobacco Enthusiasts

- Navigating the Future of HIPAA Compliant Email: Safeguarding Patient Information in a Digital Age

- Link Alternatif Santagg: Solusi Terbaik untuk Pengalaman Bermain Tanpa Hambatan

- Navigating Divorce in Atlanta: Insights from Kessler & Solomiany Family Law Attorneys

- Discovering the Best Hotels: A Guide to Finding Your Perfect Stay

- The Ultimate Guide to Catering in KL: Elevate Your Events with Exquisite Cuisine

- Capturing Love: The Art of a Wedding Photographer

- What is an Outsourcing Company? Understanding the Concept and Its Benefits

- Les Théières en Verre : Un Voyage dans l’Art de la Préparation du Thé

- Abogado Accidente Tráfico Sabadell: Tu Guía Legal Integral

- Discover the Charm of Paso Robles Wine Tours

- Mobile Phone Cover Printing Machine: Transforming Emerging Markets

- Discover the Advantages of Display Panels

- IO Expansion: A Guide to Expanding Your Input/Output Capabilities

- Elevating Efficiency: Understanding Diesel Scissor Lifts in Business

- My soul … loves you. My ego ... hates you. by the well known romanian essayist Adrian Gabriel Dumitru

- Unleashing the Power of Brain Games: Enhancing Cognitive Fitness with Brainsporthero

- NOLIMIT77: Membuka Era Baru Sensasi Kemenangan dalam Slot Online

- Milan69: Platform Terbaik untuk Taruhan Online

- LOB: De Toekomst van Leerlingfeedback met Catwise

- Crafting the Future: The Art and Science of Software Development

- Keigo Miura Exposed: The Fake Pilot Deception Unveiled Amid a Web of Drug Abuse and Fraud

- Cooking Team Building: A Recipe for Success

- The Rise of the Disposable Vape Pen: A Comprehensive Look at Lost Mary

- Finding Reliable Plumbing Services in Bristol: A Comprehensive Guide

- asasasasasas

- The Power of Power Washing: Revitalize Your Home and Business

- The Art and Importance of Book Cover Design

- Harnessing the Power of the Sun: A Comprehensive Look at the Longi 400W Solar Panel

- Unveiling the Power of Chaga Mushroom: Nature’s Hidden Treasure

- WarrenGroup: Transforming Your Home with Quality Windows and Doors

- Elevate Your Space with Chrimson Windows and Doors

- Windows and Doors: The Gateway to Quality Living

- Norcross Car Accident Lawyer: Your Guide to Legal Support After a Crash

- Norcross Car Accident Lawyer: Your Guide to Legal Support After a Crash

- Best Spotify EDM Playlist: Elevate Your Music Experience with 4D4M

- Elevate Your Vehicle’s Protection with Ceramic Coating in Vancouver

- Exploring Milan69: A Gateway to 24/7 Online Gaming Luxury

- Laimz LV: Iepazīšanās ar Inovatīvāko Tiešsaistes Kazino Latvijā

- ELS Autism/ABA Therapy App: Honoring a Legacy, Changing Lives

- Spaceman Slot: Game Slot Online Penghasil Jackpot Terbaik

- Plumber Redcliffe: Your Trusted Plumbing Experts

- Discovering the World: Your Ultimate Guide to Booking Flights, Hotels, and Trips

- Exploring the World: Your Ultimate Guide to Flights, Hotels, and Trips

- GCheck: Revolutionizing the Background Check Process

- The Essential Role of a Plumber: Keeping Your Home Flowing Smoothly

- Enhancing Your Ride: The Importance of Quality Motorcycle Windshields

- Norcross Car Accident Lawyer: Your Guide to Navigating Personal Injury Claims

- Prompt-Optimierung-für-ChatGPT: Die Kunst der perfekten Anweisungen

- ChinaPCBA: Leading the Way in PCB Assembly Services

- Your Trusted San Diego Plumbing Company: Excellence in Service and Expertise

- Discovering Supafuse: The African Music Streaming Platform Revolutionizing the Industry

- The Ultimate Relaxation Experience: Exploring the Benefits of Massage Chairs

- Affordable Plumbing Services - San Diego, CA

- Portland SEO Company: Designix Web Solutions

- Menemukan Keseruan dalam Permainan Slot di Mesin Slot Online

- Airport Fire Attorney: Your Advocate in the Aftermath of Tragedy

- Exploring the Future of Manufacturing: The Role of a Blow Molding Machine Manufacturer

- Unlocking Online Success: The Importance of SEO Services for Your Business

- Transform Your Space with Kuishi: The Elegance of Glass Soap Dispensers

- Exploring the Chevrolet Blazer: A Perfect Blend of Style, Performance, and Utility

- Stay Warm and Stylish: Why Long Sleeve Cycling Jerseys Are a Must-Have for Every Cyclist

- Menyelami Keseruan Slot Gacor di JPGACOR303

- Beste Luieraanbieding: De Ultieme Gids voor de Beste Luiers en Aanbiedingen

- Aanbieding Pampers: De Beste Keuze voor Je Kleintje

- Health Hub SG | Health Hub Singapore: Revolutionizing Wellness Through Innovation

- Menemukan Kemenangan Besar di Dunia Slot Gacor Bersama KAISAR77

- Sodium Ion Battery For Sale: A Game-Changer in Energy Storage

- Understanding Commercial Plumbing: Your Comprehensive Guide

- Hướng dẫn chơi baccarat nhatvip

- Abogados Extranjeros en Sabadell: Tu Guía para un Proceso de Inmigración Sin Complicaciones

- The Ultimate Guide to Drawer Handles: Transform Your Home with Stylish Hardware

- Koupit TikTok Followers: Jak Získat Rychlejší Úspěch na TikToku

- Unlocking the Potential of SLOT GACOR: A New Frontier in the Fight Against FGM/C

- Purificateur d'eau : La Solution Écologique pour une Eau Saine

- the kind wash: Professional Cleaning Services & Laundry Solutions for Shoes, Bags, and Baby Gear

- Your Comprehensive Guide to Buying Zopiclone Online

- Your Ultimate Guide to Shuttle from Denver to Steamboat Springs, Colorado

- Understanding Bunionectomy: A Comprehensive Guide

- Your Guide to Finding the Right Car Accident Attorney in Las Vegas

- Chiến thuật chơi Roulette và kỹ năng chơi hiệu quả

- Quay Nổ Hũ Trên rikvip - Chơi Game Nhận Thưởng Jackpot Hàng Tỷ Đồng

- Tiết lộ Chiến thuật chơi tài xỉu uk88 bách chiến bách thắng

- Discovering Paso Robles: The Ultimate Wine Tour Experience

- Exploring the DMT Vape Pen: A New Frontier in Psychedelic Experience

- Operasi Plastik Korea: Mengapa Semakin Banyak Orang Memilih Klinik Bedah Plastik MINE

- The Importance of Choosing the Right Roofing Professionals in Bernards NJ

- Hand Template Printable: Unleashing Creativity and Practicality

- Off-Road Dirt Bikes for Kids: A Comprehensive Guide for Young Adventurers

- Sklepy Internetowe Opole: Jak RED MUSTANG® Zmienia Rynek E-Commerce

- Illuminate Your Space: The Rise of LED Strip Lights from Deking

- Warren Windows and Doors: Elevating Your Home’s Aesthetic and Functionality

- Memahami Keseruan dan Strategi dalam Slot Mahjong

- Understanding China WDMA: A Leader in Windows and Doors Industry

- Unlocking the Future of Ross CA Real Estate with Diamond Group eState

- Real Estate Services in Denton County: A Comprehensive Guide

- sdsdsd\

- История и еволюция на Megaways игрит

- sdsdsd

- Unleash Your Inner Trivia Champion: Find Trivia Near You with Great Big Trivia

- Unlocking the Excitement: Your Guide to Slot Free Credit at PG Slot 2

- Understanding Lobbying Services: A Key to Influence in Texas

- Junk Removal Near Me: The Ultimate Guide to Decluttering Your Space

- Abogado Segunda Oportunidad Barcelona: Tu Solución Legal en BL Abogados Segunda Oportunidad Legal

- Optimize Your Workflow with Employee Scheduling Software: A Game Changer for Teams

- Unlocking Efficiency with Workant: The Ultimate Time Tracking App

- Unlocking Efficiency with Workant: The Ultimate Time Tracking App

- Memahami Facelift: Solusi untuk Wajah Kencang dan Awet Muda

- Unveiling Radiant Skin: The Revolutionary Hydra Pen by Labode Beauty

- Brazilian Jiu Jitsu Classes in Hutto: A Path to Self-Improvement at Pragma Jiu Jitsu

- Discover the Thrills of Climbing: A Gateway to Adventure and Personal Growth

- Discovering Scooters for Sale Near Me: A Comprehensive Guide to Q9 Power Sports

- KI Agentur: Die Zukunft der digitalen Innovation

- Cheap VPS: An Affordable Solution for Web and Game Hosting Needs

- Podwyższona Grządka Betonowa: Idealne Rozwiązanie dla Twojego Ogrodu

- The Allure of Handmade Knobs: Craftsmanship Meets Eco-Friendliness

- Transform Your Home: The Ultimate Guide to Kitchen Remodeling with Calista Homes

- The Fascinating World of Mushroom Chocolate: A New Era of Sweet and Psychedelic Delights

- Waterkoker.net: Jouw Ultieme Gids voor het Kopen van een Waterkoker

- Best Crypto Presale 2024: Uncovering the Next Big Presale Coins

- Mẹo Đánh Xóc Đĩa uk88 Siêu Hiệu Quả Đánh Đâu Thắng Đó

- Làm thế nào để đánh lô đề trúng lớn cho anh em lô thủ

- Austin HVAC TX: Ensuring Comfort with Grande Air Solutions

- Pocket Option Demo: A Comprehensive Guide to Binary Options Trading Practice

- The Power of Book Cover Design: How Creativeparamita Enhances Your Storytelling

- Pozycjonowanie Opole: Klucz do Sukcesu w Marketingu Internetowym z REDMUSTANG®

- Unlocking Business Potential with AI-Powered Lead Generation Tools

- The Ultimate Guide to Graphic Hoodies: Style, Comfort, and Versatility

- Unlocking the Power of Core HR: The Central Hub for Your HR Needs

- Thermal Protector: The Unsung Hero of Electronics Safety

- Top Texas Lobbying Firms: Navigating the Heart of Government Relations

- Unlocking the Power of Chiropractic Care: A Path to Better Health

- Tummy Tuck: Mengembalikan Kepercayaan Diri dengan Abdominoplasti di Klinik Bedah Plastik MINE

- The Ultimate Guide to Employee Absence Software: Streamlining Time-Off Management

- TrafficZest Invitation: Unlocking a New Era in Digital Traffic and Marketing

- Pocket Option: A Comprehensive Guide to Binary Options Trading

- Sexual Health: Empowering Confidence and Well-Being with Lemonly's Offerings

- Talaria: Din Ultimative Rejsepartner til Elektrisk Kørsel

- Mobilitetsscooter: Oplev Friheden med IveCar

- What to Expect When Working with a Nashville Divorce Attorney: A Comprehensive Guide

- MotoMorini: Den Perfekte Billige Motorcykel til Alle Eventyr

- Food Truck: En Verden af Smag på Farten

- Oplev Friheden med en El-Scooter: En Økonomisk og Miljøvenlig Løsning til Den Moderne Bypuls

- How to Start an AI Automation Agency: Your Step-by-Step Guide

- The Ultimate Guide to Choosing the Perfect Horse Float for Your Equine Companion

- Best Crypto Mining Rig: How to Choose the Right Crypto Mining Rigs for Maximum Profit

- Transforming Housing Society Management with Smart Billing Software: A Deep Dive into ADDA's Solution

- Mẹo Đánh Xóc Đĩa Kubet Siêu Hiệu Quả

- sasasasasasas

- Transform Your Home with the 96x80 Slider Patio Door: A Stylish, Functional Upgrade

- Everything You Need to Know About 2x6 Windows

- Physio in Abu Dhabi: Achieving Optimal Health and Wellness with AlignHealth

- Lingam Massage: A Path to Relaxation, Rejuvenation, and Connection

- The Complete Guide to Facelifts: Achieving Timeless Beauty at MineClinic

- The Ultimate Guide to Massage in McAllen: Find Relaxation and Healing with Amazing Vitality Massage

- The Rise of Pod Systems: A Convenient and User-Friendly Vaping Experience

- Buy Chesterfield Cigarettes: A Comprehensive Guide to Enjoying Premium Tobacco

- Abogado de Accidente de Tráfico en Cerdanyola: Tu Aliado Legal en Momentos Difíciles

- A Comprehensive Guide on Resume Keywords: How to Effectively Incorporate Them

- Rikvip tài xỉu tham gia chơi game thả ga kiếm tiền

- Why You Need a Riverdale Car Accident Lawyer: Protecting Your Rights After an Accident

- Understanding Double Chin: Causes, Treatments, and Solutions

- Tummy Tuck: A Comprehensive Guide to Achieving a Flatter, Firmer Abdomen

- Unlocking Success with Expert Law Tutors: Why CityLawTutors is Your Pathway to a Brilliant Legal Career

- The Future of Trading: How the Solana Volume Booster Bot Is Revolutionizing DEX Trading

- The Rise of China Articulating Boom Lifts and Their Impact on New Mexico

- Infer Stainless Steel Exhaust Pipes in Louisiana

- The Rise of Juul Kits: A New Era in Vaping

- The Future of PET Sheet Extrusion: Innovations and Solutions with TZ-Machinery

- Bật Mí Những Kinh Nghiệm Chơi Rồng Hổ Bất Hủ Cho Người Mới

- Tìm Hiểu Về Những Ứng Dụng Soi Cầu Lô Đề Hot Nhất

- Understanding the Role of an Atlanta Slip and Fall Accident Lawyer

- The Ultimate Guide to Timber and Plywood in Abu Dhabi: A Comprehensive Overview by AdBuild

- Stomatolog pentru copii: Alegerea unui specialist de încredere pentru sănătatea dentară a micuțului tău

- The Healing Touch of Lingam Massage in London: An Unmatched Experience at PureTantricMassage

- Exploring the Evolution of Fertilization Machines: A User-Centric Perspective

- Prodigious Innovations: The Fertilization Machine and Its Transport Attributes

- The Ultimate Guide to Hiring an Escondido Handyman: Your Partner in Home Improvement

- Understanding Kano Model Categories: A Key to Enhancing Customer Satisfaction

- Discovering the Art and Innovation Behind Custom Knit Sweaters: A Look at DGJIAYAN

- The Art of Book Cover Design: Unlocking the Power of Visual Storytelling

- Bật Mí Những Kinh Nghiệm Chơi Sicbo Hiệu Quả Nhất Hiện Na

- The Ultimate Guide to a Blissful Vow Renewal Experience with BlissChapel

- Warren Patio Doors: The Key to Enhancing Your Home's Elegance and Functionality

- WDMA Patio Doors: Enhancing Your Home's Aesthetics and Functionality

- The Growth and Opportunities of Export Trade: How Humblesage Food is Revolutionizing Global Foodstuff Markets

- Save Money on Helium 10: Exclusive Coupon Codes Explained

- Solana Volume Booster: The Future of Blockchain Scaling

- Unlocking the Power of the Solana Volume Booster Bot: A Game-Changer for Crypto Traders

- Reparación de Neveras en Bogotá: Garantiza el Buen Funcionamiento de tu Electrodoméstico

- Understanding Breast Augmentation: A Comprehensive Guide by MineCLinic

- Understanding Employment Law in the UK: A Step Towards Fairer Practices

- Explore ICV.Bio’s Advanced Features

- Gates of Olympus: Keajaiban Slot Online yang Menghadirkan Sensasi Jackpot Maksimal

- Abogado Segunda Oportunidad Barcelona: La Solución a tus Problemas Financieros

- Achieving a Sculpted Jawline: The Road to Confidence and Beauty

- The Importance of Choosing the Right Chimney Company: A Guide to Certified Chimney Connecticut

- Mental Health Support in Corpus Christi: A Path to Healing and Wellness

- Finding the Right Dentist in Burlington: Your Guide to GroveDentistry

- MMA Utstyr: Essensielt for Din Kamptrening

- Decentralized Masters Reviews: Is This Crypto Opportunity Worth Your Time and Money?

- Top Remote Job Platforms for Indians in 2024

- Exploring Weird Topics: The Oddities That Capture Our Imagination

- Mengoptimalkan Kontur Jawline Anda di Klinik Bedah Plastik MINE: Solusi Terbaik untuk Penampilan yang Lebih Tegas

- Why The Last of Us Series Remains a Masterpiece in Gaming History

- Movers: The Key to a Stress-Free Relocation Experience

- Houston Vending Services: Your Trusted Partner for Workplace Convenience

- Mercedes V Class Hire with Driver Marrakech: The Ultimate Experience in Comfort and Style

- Fontaneros Bilbao: Soluciones Rápidas y Eficientes de Fontanería con FontanerosExpress247

- Neck Lift: A Comprehensive Guide to Rejuvenating Your Neck and Jawline

- The Rise of Korean Plastic Surgery: A Global Beauty Phenomenon

- Unlocking the Power of Rejuran: A New Era in Skin Rejuvenation

- How to Get Monetization for X (Twitter): A Step-by-Step Guide

- Unlocking the Power of Staking Rewards with EBM Avenue: A Sustainable Future in Crypto

- Understanding the Importance of a Child Psychologist: Supporting Mental Health in the Early Years

- Exploring the Thrills of Tongits: A Fun and Engaging Card Game by GameFun

-

The Future of Packaging: How PET Sheet Extrusion Lines are Revolutionizing Industries

- Apprehension Speech Processors and Their Role in Customer Retention

- The Future of RFP Management: How BidWizard is Revolutionizing the Process with AI-Driven Technology

- The Importance of a Podiatrist: Caring for Your Feet and Beyond

- Advocate for Recruitment CRM Software: Transforming the Transportation Industry!

- Lingam Massage in London: A Journey of Relaxation and Sensuality

- Cuci Karpet KL: The Essential Guide to Carpet Cleaning in Klang Valley

- Panorica - Hybrid & Electric Cars: Driving the Future of Sustainable Transportation

- Valorant Smurf Accounts: Everything You Need to Know

- Telegram官网:探索隐藏信息与高级配置技巧

- Alquiler de Autobuses Zaragoza: La Solución Ideal para tus Viajes Grupales con Autocares Monsegur

- Everything You Need to Know About Disneyland Tickets 2025: Your Ultimate Guide

- Top Influencers in Crypto: Shaping the Digital Currency Landscape

- Selamat Datang di Janji Gacor: Rasakan Sensasi Menang Besar di Dunia Slot Gacor

- Boosting Your Streaming Success: The Power of Kick Bots Viewers

- Comment se procurer de la morphine : Tout ce que vous devez savoir

- Kick Viewer Bot: Boosting Your Streaming Success with ViewerBoss

- Proven Affiliate Marketing Strategies: A Step-by-Step Guide to Earning $100/Day with ClickBank Using AI-Powered Tools

- Phần Mềm Quản Lý Tiệm Nail: Giải Pháp Hiện Đại Cho Chủ Tiệm Nails Chuyên Nghiệp

- AIvideo: Revolutionizing Content Creation with Artificial Intelligence

- Understanding the Power of Company Financial Reports: How Financh is Transforming Business Intelligence

- 리쥬란: 피부 재생의 혁신적인 솔루션a

- بت 212: دنیای جدیدی از هیجان شرط بندی و خدمات برتر

- Discover the Comfort and Freedom of Riverview Townhomes at Latitude27Riverview

- Discover Luxury Living: Spacious 1-3 Bedroom Apartments at Sentosa Lexington Oaks

- 온라인카지노 추천: 안전하고 신뢰할 수 있는 최고의 카지노 사이트 찾기a

- 중고화물차: 비즈니스에 적합한 최적의 선택a

- The Hydra Pen: Revolutionizing Skin Care with K-Beauty Innovation

- How Working Past 65 Impacts Your Medicare Choices

- Breast Lift: The Path to Confidence and Transformation

- Understanding Liposuction: A Guide to Safe and Effective Body Contouring at MINE Clinic

- Telegram下载:探索无界沟通的未来

- Telegram中文版:探索与了解

- 自体脂肪丰胸:饱满与安全兼具的美丽之选a

- 隆胸手术:重塑自信的秘密a

- 面部拉皮:双重紧致的魅力与效果a

- 双下巴的困扰与解决方案:塑造完美下颌线条a

- Socks Manufacturer in India: The Rise of Sock Republic

- 美版超声刀:开启非手术抗衰新时代a

- Tummy Tuck: Transformasi Tubuh yang Menyempurnakan Penampilan Anda di Klinik Bedah Plastik MINE

- The Ultimate Guide to NSFW Story Generators: Unleashing Creativity and Understanding the Impact

- Understanding Breast Reduction Surgery: A Comprehensive Guide

- Unlocking the Future of Blockchain Development: The Role of Code Editors in the AI-Powered Blockchain Ecosystem

- AI Crypto: Revolutionizing Blockchain Development with Reploy’s AI Ecosystem

- The Power of Book Cover Design: Why It’s Crucial for Your Book’s Success

- The Ultimate Guide to Dresses: Unveiling Fashion Trends with Trending Chic

- The Timeless Appeal of Dresses: Elevating Your Wardrobe with Trending Chic

- Everything You Need to Know About 9-Foot Garage Doors

- Understanding the Importance of a 72-Inch Window: A Comprehensive Guide

- How to Instantly Download Instagram Videos for Free with InstaFreeVideoDownload

- Unlocking Career Success with Instant CV: The Future of Resume Building

- Plumbing Company King County WA: Your Trusted Partner for Plumbing Services

- Feskov: La Medicina Riproduttiva e i Diritti Umani per un Futuro Migliore

- Law Firm Marketing: A Roadmap to Success in the Digital Age

- Law Firm SEO: Unlocking the Power of Digital Marketing for Legal Practices

- Pomoc Drogowa Włodawa: Jak Wybrać Najlepszą Usługę dla Swojego Pojazdu

- Dompogrzebowynadzieja.pl – Profesjonalna pomoc w trudnych chwilach

- Operasi Plastik Korea: Pilihan Tepat untuk Kecantikan dan Kepercayaan Diri

- Mengatasi Double Chin: Solusi dan Perawatan Terbaik di Klinik Bedah Plastik MINE

- Facelift: Transformasi Kecantikan dan Kepercayaan Diri di Klinik Bedah Plastik MINE

- Unlocking the Power of Law Firm SEO: Strategies for Success

- Home Renovation Company Sydney: Transform Your Space with Probuild Construction Team Pty Ltd

- Buy Weed Online Australia: The Ultimate Guide to Cannabis Delivery in Australia

- Buy THC Gummies in Australia: Your Guide to Safe and Discreet Cannabis Enjoyment

- 잠실 윈가라오케: 송파구 최고의 노래방 경험a

- 잠실 윈가라오케: 송파구 최고의 노래방을 만나다a

- El Paso Personal Injury Lawyer: Your Advocate for Justice and Recovery

- JY娛樂城:打造線上娛樂的全新體驗

- 메이저놀이터 추천: 안전하고 신뢰할 수 있는 선택을 위한 가이드a

- The Power of Custom Statues: Enhancing Interior Décor and Artistic Expression

- Unlocking the Secrets of Relaxation: The Transformative Power of Lingam Massage in London

- Streamline Your Lyft Inspection with Insve: The Fast, Convenient, and Affordable Solution

- Lyft Online Inspection: Streamlining the Process with Insve

- WarrenGroup Windows and Doors: Elevating Your Home with Expert Solutions

- Bi-Folding Windows and Doors: The Future of Modern Living

- Wedding Invitations: A Reflection of Style and Personalization

- Norske OnlyFans Profiler: Din Ultimate Guide til Suksess på Ektefans

- Exploring Zeppelin Bet: An Engaging and Responsible Gaming Experience with Sokabet

- Photography: Capturing Moments That Last a Lifetime

- The Best Airsoft Guns: A Comprehensive Guide for Enthusiasts

- 인터넷 슬롯 머신 사이트: 게임의 매력과 선택 가이드a

- Water Damage in Huntington Beach: How Restoration1 Can Help You Recover

- Katy Wrongful Death Lawyer: Navigating the Legal Path After a Tragic Loss

- Situs Judi Togel: Mengapa Seadoghull Adalah Pilihan Terbaik untuk Pemain Togel Online

- 翻譯社:數位時代的語言橋樑與未來的發展a

- Compro Orologi Torino: La Tua Guida Completa da FG Watches

- Discovering the Best Property for Sale in Richmond Hill: A Guide by Homsy

- Mpo1881: Situs Slot Deposit Pulsa Terpercaya untuk Pengalaman Bermain Gacor

- Slot QRIS: Metode Deposit Terpercaya dan Terjangkau di MPO1551

- Trump Tower Jeddah: A Pinnacle of Luxury and Modern Architecture

- Exploring the Appeal of Apartments in Riverview, FL: A Modern Living Destination

- DoldAdress: Säkerhet För Ditt Personliga Liv Online

- Riksskydd: Hur Du Skyddar Din Personliga Information Online

- How to Buy Dinar: A Complete Guide

- Safedinar: A Comprehensive Guide to Currency Exchange with Dinarit

- Deneme Bonusu Veren Siteler: Unlocking the Benefits of Free Bet Offers in Online Gaming

- Deneme Bonusu Veren Siteler: A Comprehensive Guide to Exploring and Maximizing Online Bonuses

- 함몰유두: 이해하고 개선하는 방법a

- Ceramic Coating Vaughan: Protecting Your Vehicle with Premium Quality

- How AgilityPortal’s Employee Communication App is Connecting Employees

- Understanding Double Chin: Causes, Solutions, and How MINE Clinic Can Help

- The Ultimate Guide to Facelifts: Redefining Beauty with MINE Clinic

- FurryBabiesDubai: The Best Pet Shop in Dubai for Your Furry Friends

- Chess Coaching: Empowering the Next Generation of Strategic Minds

- The Power of Premade Book Covers: How CreativeParamita Transforms Your Story Into Visual Art

- 먹튀검증사이트: 안전한 온라인 토토를 위한 필수 정보a

- Portland Premises Accident Lawyer: How to Seek Justice and Compensation

- Exploring the Elegance and Functionality of 80 Inch French Doors

- The 48-Inch Window: The Perfect Choice for Modern Homes and Buildings

- Mengenal Perawatan Jawline: Meningkatkan Penampilan dengan Klinik Bedah Plastik MINE

- Reparación de Televisores en Bogotá: Soluciones Rápidas y Eficaces para Todos los Modelos

- 200 Hour Yoga Teacher Training in Rishikesh: A Transformative Journey at HimalayanYogAshram

- بلیط هواپیما: راهنمای جامع برای انتخاب بهترین گزینه سفرa

- قیمت بلیط هواپیما: راهنمای جامع برای مسافرانa

- The Power of MLS Ontario: How Homsy is Changing the Real Estate Game

- チタニウムリフト:最新の美容技術がもたらす効果とは?a

- Double chin problems and how to get rid of them: Solutions provided by Mine Dermatology

- フェイスリフトの魅力と効果的なアプローチa

- Exploring the Magic of Desert Tours in Morocco: Your Ultimate Guide with Desert Trips Morocco

- Merzouga Trip: An Unforgettable Journey into Morocco’s Sahara Desert

- Affiliate Marketing Plan: The Ultimate Guide to Building a Profitable Strategy

- The Power of List Building Software: A Key to Business Growth and Success

- 垂れ乳とは?原因と解決策を探るa

- Abogado de lo Penal: ¿Por qué es importante elegir el adecuado para tu defensa legal?

- บัญชี Facebook: กลยุทธ์ในการเพิ่มประสิทธิภาพและการเติบโตในโลกออนไลน์

- PDF to CSV Bank Statement: A Comprehensive Guide to Seamless Conversion

- How to Convert Bank Statement PDF to Excel: A Step-by-Step Guide

- Exploring Houses in Vaughan: Your Gateway to Smart Real Estate with Homsy

- Unlocking Productivity: The Role of Employee Communication Apps in Modern Workplaces

- Amazon Product Testing: A Strategic Approach to Quality and Innovation by Qalitex

- The Essential Guide to SPF Cream Testing: Why It Matters and How It’s Done

- Finding the Best Real Estate Agent Near Me: A Guide to Success

- Firmafrokost – En Kulinarisk Oplevelse til Dit Arbejdsfællesskab

- Unlocking Career Opportunities: The Power of Apprenticeships

- Mastering the ICAO Exam: Your Gateway to Aviation Excellence

- Understanding ICAO Level 6 and Its Importance in Aviation Careers

- The Ultimate Massage Chair: A Traditional Experience with a Modern Twist

- The Art of Chinese Swords: A Look at the Jian and Dao

- The secret to building a successful, sustainable business

- Change the way you do business to be memorable

- Casino Community: The importance of a platform for sharing online casino information

- Major Site: How to Find a Safe and Trustworthy Online Casino

- The Global Allure of Korean Plastic Surgery: Redefining Beauty with Precision and Innovation

- Vaping Devices: The Future of Smoking and the Rise of Off-Stamp Innovation

- Taipei Stress Relief Center: Embrace a moment of tranquility in life

- Bank Statement Converter: Revolutionizing Financial Data Management with StatementSheet

- Microlene Filter: Essential for Clean Water and Appliance Longevity

- Microlene Filter: Essential for Clean Water and Appliance Longevity

- The Ultimate Guide to Fisher and Paykel Fridge Water Filters: Keeping Your Water Clean and Your Fridge Efficient

- How to Transform Shopping into a Rewarding Experience with Meshada Fashion

- Unlock the Power of Fashion with Cashback Rewards

- MLS Toronto: The Gateway to Efficient Home Buying and Selling in Toronto

- Abogado de lo Penal en Barcelona: Defiende tus derechos con los mejores expertos en derecho penal

- Abogado Barcelona: La Defensa Criminal con Barna Legal Defensa Penal Barcelona

- Transforming Your Home with a Contemporary Living Room: A Guide to Modern Elegance

- The Power of a Book Cover: Why Choosing the Right Book Cover Designer Is Crucial for Success

- Korean Facelift: The Secret to Timeless Beauty at MineClinic

- Moving Made Easy with Ashland MA Movers: Your Ultimate Guide to a Seamless Relocation Experience

- Packing Services in Ashland, MA: Your Stress-Free Moving Solution

- Well Pump Repair in Forsyth: Expert Services by WellWatchersWellPumpServices

- Curtain and Blind Makers: Quality Craftsmanship and Personalised Service

- Akun Iklan MCY Agency: Solusi Efektif untuk Kampanye Digital yang Sukses

- Unlocking Career Success: How Law Tutors Can Help You Bridge the Gap to Legal Employment

- Navigating the SQE1: A Pathway to Legal Success with CityLawTutors

- Buhalterinė apskaita: Kodėl tai yra nepakeičiama Jūsų verslui?

- Virtual Tours: A Revolutionary Way to Explore the World from Home

- MLS Listings Toronto: Your Ultimate Guide to Finding the Perfect Home

- Cutting-Edge Tech Innovations: Shaping the Future of Electronics & Gadgets

- Data Recovery London: The Essential Guide to Data Recovery Services

- Facelift phone: reshape youth, restore self-confidence

- Exploring the Market Attributes of Energy Storage Solutions

- The Essential Guide to Pre-Insulated Ductwork: Efficiency and Innovation with VENTECH

- Slot QRIS: Cara Mudah dan Cepat Melakukan Deposit di MPO1881

- How to Sell on Amazon: Expert Tips and Strategies for Maximizing Your Sales Potential

- MPO1881: Solusi Mudah dan Praktis untuk Deposit Slot Online dengan QRIS

- The appeal and latest technology of breast augmentation surgery: Mine Cosmetic Surgery and Dermatology's approach

- Finding African Clothing Stores Near Me: A Gateway to Heritage and Style

- The 24Hour Challenge: A Revolutionary Way to Boost Your Productivity and Self-Discipline

- Casino Community: Introduction to Korea’s best online casino sites

- Free Slots: Explore the world of free slot games in the casino community

- Finding the Best Quran Memorization Classes Near Me: A Path to Spiritual Growth and Knowledge

- Flashlight Stun Batons: Your Ultimate Self-Defense Tool

- Magnetic Door Window Alarm: Enhancing Home Security with Black Belt Defender

- Z-Library: Revolutionizing Access to Knowledge in the Digital Age

- B-OK Z-Lib: Exploring the World’s Largest eBook Library

- The Art of Book Cover Design: Crafting Visual Masterpieces that Sell

- The Power of Horror Book Covers: Designing the Perfect Visual Hook

- Colored Contacts: Transform Your Look with Confidence and Comfort

- Contemporary Dining: A Fusion of Style, Function, and Personalization at HOME ATELIER

- Modern Interior Design Ideas: Transform Your Home with Timeless Style

- Disability Insurance Lawyers: Your Advocate in the Fight Against Wrongful Denials

- Disability Insurance Lawyers: Protecting Your Rights with Eric Buchanan and Associates

- Arthuryoria: Mengungkap Potensi dan Peranannya dalam Dunia Permainan Online OLXTOTO

- Unlocking Efficiency in Real Estate: The Homsy Advantage

- Loudly: The Freezer Inventory Management Software That Will Change Your Life (and Your Frozen Peas)

- Shining Bright: The Rise of Split Solar Street Lights in the UK!

- Unlocking the Potential of Passive Income: A Path to Financial Freedom

- Unlocking Your Earning Potential: How Vantage Quest Can Empower Your Financial Success

- Plumber in Brooklyn: Why AC Drain Cleaning LLC is the Go-To Choice

- Importance and latest trends of jawline cosmetic surgery: Mine Plastic Surgery’s professional approach

- The Importance of Independent Financial Advice for Securing Your Financial Future

- 10 Social Media Post Ideas That Will Get Followers

- How to Search Home Listings Efficiently: A Guide to Finding Your Dream Home

- Renowned Data Center Events Hong Kong: Navigating Legal and Regulatory Landscapes

- The Ultimate Guide to Choosing a Singapore Maid Agency: Trusting Experts in Domestic Help

- The Ultimate Guide to Choosing a Home Renovation Company in Sydney

- Unlocking Success with SEO Services in Sydney: A Guide for Local Businesses

- How Jescojes Jewelry Can Help You Celebrate the Protagonist in Your Life

- Exploring the Legal Landscape of Oligo Synthesis

- Enhancing Your Jawline: The Key to a Confident, Sculpted Look at MINE Clinic

- Discover the Perfect Luxury Living at St. Johns, FL Apartments

- Abogados Accidentes: Tu Guía Completa para Obtener la Compensación que Mereces

- Annapurna Circuit Trek: A Journey Through the Heart of Nepal

- Discovering the Perfect Blinds Shop for Your Home or Business

- Electric Curtains: The Future of Home and Office Comfort

- MLS Listings Toronto: Your Ultimate Guide to Finding the Perfect Home

- The Rising Influence of Pixel RGB Light in Modern Marketing Strategies

- Oregon City Car Accident Lawyer: Protecting Your Rights with Attorney Wolfe

- Oregon City Personal Injury Lawyer: Protecting Your Rights and Securing Your Future

- Seeking Justice with a Santa Rosa Wrongful Death Attorney: A Path to Healing and Accountability

- sds

- Santa Rosa Wrongful Death Attorney: Your Guide to Seeking Justice and Compensation

- The Ultimate Guide to the Korean Face Lift: Revolutionary Beauty from MineClinic

- Why Perth Blockout Curtains Are the Secret to Transforming Your Home's Comfort and Style

- The Ultimate Guide to Buying Wana Gummies Online: Benefits, Considerations, and Tips for Cannabis Enthusiasts

- Luxurious Virtual Data Centre Services: Transforming the Interactive Maps Market

- Buy London Chello Cookies Online: The Ultimate Hybrid Experience at Zilli Weed

- Everything You Need to Know About Custom DTF Gang Sheets: The Ultimate Solution for Bulk Printing

- Unlocking the Power of a Mini Facelift: A Revolutionary Approach to Youthful Skin

- Understanding the Role of a Pensacola Personal Injury Attorney

- Korean Plastic Surgery: The Global Beauty Trend Shaping Faces and Futures

- The Future of Money? Exploring the Impact of Central Bank Digital Currencies

- Unlocking the Power of a Property Value Calculator: How to Maximize Your Real Estate Experience with Homsy

- The Benefits and Features of a Ductless Range: Why Ciarra Is Leading the Way

- Portable Range Hoods: The Perfect Solution for Modern Kitchens

- Gainesville, GA Wrongful Death Attorney: Pursuing Justice and Healing with Davies Hothem Injury Law

- Gainesville, GA Wrongful Death Attorney: Seeking Justice for Your Loved One

- Mengenal Dunia Slot Online: Mengapa RRQ88 Menjadi Pilihan Terbaik?

- Finding Your Dream Home with MLS Toronto

- Revolutionizing Energy: Latest Battery Technology in the Physical Maps Market - Oct 2023 Insights

- Mengapa Alexis17 Menjadi Pilihan Utama Pemain Slot di Indonesia

- Agen Slot Gacor: Pilihan Terbaik untuk Menang Besar di Dunia Slot Online

- Menjadi Pemenang di Dunia Slot Online: Mengapa Slot777 dan Kaisar77 Jadi Pilihan Utama

- Abogados Seguridad del Tráfico Barcelona: Protección Legal en Casos de Delitos contra la Seguridad Vial

- The Power of Book Cover Design: How Creativeparamita Transforms Your Story Into Visual Art

- Everything You Need to Know About 9 Feet Garage Doors: A Complete Guide

- Everything You Need to Know About the 48-Inch Window

- Remarkably Efficient: The All-in-One Solar Street Light Revolution

- WarrenGroup Window: A Game-Changer in Window and Door Solutions

- The Ultimate Guide to Buying Kanha Gummies Online: A Journey into Cannabis Infused Delights

- Chrimson Window: The Future of Home Design and Sustainability

- Judul: Menjadi Raja Slot Online di SLOT88MAX: Pengalaman Bermain Slot Gacor Terpercaya di Indonesia

- Mengenal Bonnerfide Radio: Inovasi dalam Dunia Hiburan yang Berkualitas

- Judul: Keuntungan Bermain di Situs Toto Terpercaya: INFITOTO sebagai Pilihan Utama

- Togel Singapore: Panduan Lengkap dan Keuntungan Bermain di INFITOTO

- The Ultimate Guide to Buying Junglato Jungle Boys Online: A Flavorful Cannabis Experience

- The Rise of Diet Smoke Gummies: A Healthier Way to Enjoy Cannabis

- KEBUNTOTO Daftar: Panduan Lengkap untuk Meningkatkan Peluang Anda Menang dalam Togel 4D

- Data Recovery in Edinburgh: A Comprehensive Guide by DataClinic

- Tile or Slate Roofing: A Durable and Stylish Choice for Your Home

- Operasi Plastik Korea: Mengungkap Tren dan Manfaatnya di Klinik Bedah Plastik MINE

- Meningkatkan Profil Anda: Segala yang Perlu Anda Ketahui tentang Pembentukan Jawline

- Unlocking the Secrets of Permanent Makeup Training: A Guide for Aspiring Artists

- Yalla Shoot

- Yalla Shoot

- What is ODG?

- Understanding the Role of a Lawyer: Why Griffin, Cain & Herbig, Attorneys at Law, PLLC, Is Your Trusted Partner

- Criminal Defense in The Woodlands, Texas: A Path to Protection and Justice

- Korea Slot: 안전하고 신뢰할 수 있는 슬롯 게임의 세계

- Discovering the Best Hair Salons in Salt Lake City: Quality, Pricing, and Experience

- Austin Truck Accident Lawyer: Fighting for Justice on Your Behalf

- North Carolina Personal Injury Attorney: Your Advocate in Times of Crisis

- The Future of Korean Breast Augmentation: A Comprehensive Guide to HD Endoscopy and One-Day Surgery

- The Ultimate Guide to Finding the Best Hair Salon in Salt Lake City

- Abogado Accidente de Tráfico: ¿Por Qué Es Crucial Tener Un Abogado Especializado?

- Mejor Abogado de Accidente de Tráfico en Barcelona: ¿Por Qué Elegir Accireclama?

- Exploring the Power and Benefits of Lingam Massage in London

- MLS Richmond Hill: How Homsy Transforms Your Real Estate Journey

- Understanding the Role of a Sexologist in India: Why Professional Help Matters

- The Role of a Sexologist in India: Transforming Lives with Expertise and Compassion

- Enhancing Legal Careers with Expert Law Tutors

- Enhancing Legal Careers with Expert Law Tutors: A Vital Resource for Success

- The Ultimate Guide to Gold Coast Clear: Revolutionizing Cannabis Concentrates

- Best MLM Software: Empowering Your Network Marketing Success

- BN94-11930A: The Key to Fixing Your Samsung TV - A Comprehensive Guide

- The White Horse Temple: A Journey Through Time and Spirituality

- Unlocking Success in Law School: Why Law Tutors Are Essential for Aspiring Legal Professionals

- The Importance of Law Tutors: A Strategic Investment for Legal Success

- Comment Transformer Votre Entreprise en Une Machine de Succès : Stratégies Puissantes pour Dominer le Marché

- The Importance of Choosing the Right Lab Table for Your Laboratory Needs

- Travail en ligne : Une révolution du monde professionnel

- Why OpusAndCoMarketing is the Best Affordable Full-Service Digital Marketing Agency for Small Businesses

- Buford, GA Personal Injury Attorneys: Advocating for Justice and Healing

- Finding the Best Roofing Contractor in Cherry Hill: Why American Quality Remodeling Should Be Your First Choice

- Unlocking the Secrets of Effective Law Tuition: A Guide to Success

- Law Tutoring: Unlocking Your Legal Potential with Expert Guidance

- The Power of Booklet Printing: Enhance Your Brand with Professional Print Solutions

- Animator dla dzieci – Jak Tworzymy Wydarzenia, które Zapadają w Pamięć?

- Unlocking the Secrets to Choosing the Best CA in Jaipur for Your Business Growth

- Understanding Varicose Veins and Peripheral Artery Disease: Causes, Risks, and Treatment Options

- SaveFromInsta: The Ultimate Solution for Fast and Easy Instagram Content Downloads

- Mengatasi Double Chin dengan Klinik Bedah Plastik MINE: Solusi Estetika yang Modern dan Aman

- Casino utan spelpaus: En Guide till Spelupplevelsen på Utländska Casinon

- The Essential Role of Law Tutors in Shaping Tomorrow's Legal Experts

- Mastering SQE 1: A Key Step in Your Legal Career

- House for Sale in Markham: Discover Your Perfect Home with Homsy

- Understanding Gangrene and Effective Vein Disease Treatment: A Comprehensive Guide

- Understanding Statutory Redundancy Pay: Your Rights and How to Claim

- Understanding Unfair Dismissal Claims: Your Guide to Employment Rights

- Balloon Decor in Atlanta: Elevating Your Event with Stunning Designs

- Animacje Urodzinowa: Klucz do Niezapomnianej Zabawy dla Dzieci

- The Ultimate Guide to TV Screens A2182734A: Choosing, Repairing, and Maintaining Your Display

- Effective Treatments for Chronic Neck Pain and Stiffness, and Poor Bone Density

- Best Crypto Recovery Services: How RecoverMyCryptoWallet Can Help You Retrieve Lost Cryptocurrency

- Las Vegas RZR Tours: A Thrilling Adventure Awaits

- Unlocking the Power of Advertiser Campaign Management Software

- Toronto Apartments for Sale: Your Guide to Finding the Perfect Home

- Slot88: Keuntungan Gacor dengan MEMORI88

- Situs Slot Thailand: Pilihan Terbaik untuk Pengalaman Bermain yang Menguntungkan di ALEXISTOTO

- Facelift: Solusi untuk Tampilan Lebih Muda dan Segar di Klinik Bedah Plastik MINE

- Benihtoto: Platform Togel Online Terpercaya dengan Peluang Menang Besar!

- Microsoft 365 Compliance Software: Ensuring Security and Regulatory Adherence

- Finding the Right Burlington Roofing Contractor: Why American Quality Remodeling Stands Out

- Simplifying Compliance: The Power of Plug-and-Play Compliance Software Integrated with Microsoft 365

- Why Commercial & Office Cleaning Services in Toronto Are Essential for Your Business Success

- The Rise of Rechargeable Disposable Pod Systems: A Sustainable and Convenient Choice for Vaping Enthusiasts

- Abogado de lo Penal en Barcelona: La Defensa que Necesitas

- Melbet Bangladesh: The Ultimate Betting Experience for Bangladeshi Players

- The Rise of Solar Power: Why Fresno, CA is Leading the Charge in Clean Energy

- The Rise of Solar Energy in Fresno: A Bright Future for Homeowners

- UltimateShop: The Future of Seamless Online Shopping